Is Investing at Today’s Concrete Mixer Plant Price Worth It for Builders and Developers?

- aimixglobal5

- Aug 18, 2025

- 4 min read

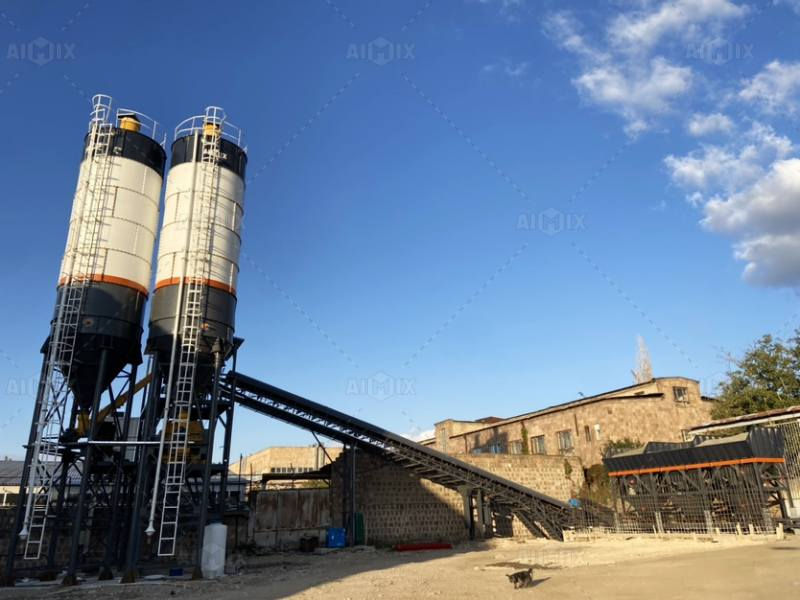

The construction industry is evolving rapidly, driven by urbanization, infrastructure growth, and rising demand for high-quality concrete. For builders and developers, one recurring question is whether investing in their own concrete mixer plant is a smart move. With competitive markets and fluctuating construction material prices, understanding whether today’s concrete mixer plant price justifies the investment is crucial.

Owning a batching plant allows companies to control their concrete supply, improve quality consistency, and reduce dependence on third-party suppliers. Yet, cost remains one of the most significant factors influencing this decision. Builders often ask: how much does a concrete batch plant cost, and is it worth the investment in today’s market?

Understanding Concrete Mixer Plant Price

The price of a concrete mixer plant varies widely depending on capacity, technology, level of automation, and configuration. Small mobile units are typically more affordable and designed for temporary projects, while large stationary plants with advanced systems command higher prices.

Small mobile plants: Often priced between $30,000–$80,000, ideal for small to medium projects or contractors handling short-term jobs.

Medium-capacity stationary plants: Range from $100,000–$200,000, suitable for continuous use in housing developments, commercial construction, or medium-scale infrastructure projects.

High-capacity plants with automation: Can cost $250,000 or more, equipped with modern control systems, real-time monitoring, and eco-friendly features.

Thus, when considering the concrete mixer plant price, builders must align their budget with the type of projects they aim to execute.

Cost vs. Long-Term Savings

One of the biggest advantages of owning a batching plant is reducing reliance on external ready-mix suppliers. While the upfront concrete mixer plant price may seem high, the long-term benefits often outweigh initial costs:

Reduced per-cubic-meter cost – Producing concrete in-house is often cheaper than buying from third parties, especially for projects requiring large volumes.

Lower transportation expenses – Contractors save money by eliminating the need to transport ready-mix concrete over long distances.

Improved scheduling – Having a plant on-site ensures concrete is available when needed, preventing costly project delays.

Quality control – Builders can maintain consistent mix designs, ensuring compliance with project specifications.

When compared against these savings, today’s concrete mixer plant price becomes a strategic investment rather than just an expense.

How Much Does a Concrete Batch Plant Cost to Operate?

Beyond the purchase price, developers should also consider operational costs. Many ask not only how much does a concrete batch plant cost to buy, but also how much it costs to run. Key expenses include:

Energy consumption: Powering mixers, conveyors, and control systems.

Water and admixtures: Essential for concrete production and quality control.

Labor: Skilled operators and technicians are required for smooth operation.

Maintenance and spare parts: Regular servicing ensures the plant operates efficiently and avoids costly downtime.

Fortunately, modern plants are increasingly designed for energy efficiency and ease of maintenance. For example, IoT-enabled systems allow operators to monitor energy usage, reducing waste and minimizing operating expenses.

Market Opportunities Supporting Investment

The timing of an investment also matters. Currently, many emerging economies in Asia, Africa, and Latin America are experiencing massive infrastructure growth. Roads, bridges, residential housing, and industrial developments are pushing demand for ready-mix concrete higher every year.

By investing in their own plant, developers can secure a reliable supply chain in these fast-growing markets. In regions where ready-mix suppliers are limited, having an in-house batching plant can provide a competitive edge. Builders are better positioned to win contracts because they can guarantee supply without relying on external vendors.

The Role of Technology in Value Creation

Another reason today’s concrete mixer plant price may be worth the investment is technology. Modern batching plants come equipped with automation, computerized controls, and remote monitoring. These systems reduce human error, enhance efficiency, and increase overall plant productivity.

For example:

Automated weighing systems ensure precise proportions, improving concrete quality.

PLC-based control systems allow easy operation and faster production cycles.

Eco-friendly features such as dust collectors and water recycling support compliance with environmental standards.

In markets where sustainability is becoming a requirement, these innovations add value beyond cost savings.

Risk Factors to Consider

While there are clear advantages, builders should also consider potential risks before purchasing. Factors such as project pipeline, local regulations, and financing availability play a role in determining whether today’s concrete mixer plant price aligns with business goals.

Project size and frequency – Companies with only small, one-time projects may not benefit as much as those with continuous work.

Regulatory requirements – Some regions require permits for batching plants, which can increase lead time.

Financing and cash flow – Contractors must balance upfront investment with working capital for other aspects of construction.

Carefully analyzing these elements ensures the investment delivers returns rather than becoming a financial burden.

Conclusion: Is It Worth It?

So, is investing at today’s concrete mixer plant price worth it for builders and developers? The answer depends on project scale, market conditions, and long-term vision. For companies involved in continuous construction projects—such as housing estates, infrastructure works, or commercial developments—the investment is often highly cost-effective.

Asking how much does a concrete batch plant cost is only the first step. Builders must also consider lifetime savings, operational efficiency, and competitive advantages gained by owning their own equipment. With modern technology and growing demand worldwide, a batching plant can be one of the most valuable assets a construction company owns.

For builders looking toward growth and independence, today’s concrete mixer plant price represents not just an expense, but a strategic investment in long-term success.

Comments